Smart reforestation

With TREEO, STIHL effectively and verifiably stores carbon through sustainable reforestation projects

STIHL manufactures products for use in forests, woodlands, and gardens. We therefore have a special ecological responsibility and use our capabilities to help protect nature and the climate. We want to conserve resources and minimize the environmental impact of our tools and business activities.

STIHL observes the environmental protection regulations that apply to it in all countries where it has plants, both in terms of manufacturing and its products. The key regulatory frameworks to which we are subject include the European Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation and the EU’s Restriction of Hazardous Substances Directive (RoHS). In the 2024 reporting year, many analyses of components and products demonstrated compliance with these requirements.

Our own environmental and quality standards are often stricter than those required by law. Where it is not possible to avoid the use of potentially hazardous substances, we always act in accordance with the regulations and standards and do everything in our power to keep the environmental impact of our business activities to an absolute minimum. We have continued to carry out an inventory of all critical process chemicals in our production. A sustainable concept for dealing with critical process chemicals takes a number of different aspects into account, such as environmental compatibility, occupational health and safety, the conservation of resources, and social responsibility. The individual measures include evaluating the necessity of critical process chemicals and considering sustainable alternatives. Additional ways to reuse, recycle, and recover chemicals also need to be investigated in the interest of a circular economy. With this we will make a contribution to the United Nations target of achieving environmentally sound management of chemicals (SDG 12).

All of the STIHL production companies worldwide, as well as all locations of the ZAMA Group subsidiary, have a certified environmental management system in line with ISO 14001. Recertification takes place every three years, with additional annual external audits. The current certificates for the German STIHL locations can be viewed publicly on our corporate website. Regular internal audits supplement the external audits. Environmental officers at each of our plants are responsible for compliance with laws, standards, and guidelines.

STIHL primarily requires water for certain production processes, namely washing, cooling, and machining. We are working to reduce our water consumption even further.

During some manufacturing processes, water is mixed with additives to act as a cleaning agent or to finish surfaces. We treat the resulting effluents in accordance with the applicable regulatory requirements before releasing them into wastewater collection systems. A water treatment plant with an annual capacity of 50,000 cubic meters went into operation at STIHL Brazil in 2024, which has halved the plant’s wastewater volume. In addition, ZAMA has put a rainwater catchment basin with a capacity of 200 cubic meters into operation at its site in the Philippines. ZAMA will use the water to flush toilets in a new building, among other things.

In 2024, the total volume of water extracted by all production companies amounted to around 557,000 cubic meters (previous year: 581,000 cubic meters).

The majority of the waste generated by the STIHL Group is made up of packaging, wood, metal, and plastics. We also generate smaller amounts of hazardous substances such as used oil and metal-containing sludge. The latter is disposed of professionally. Our approach to waste management follows the principles of prevention, recycling, and disposal. We sort the resulting waste. If possible, it is reused or recycled. If not, it is properly disposed of. During annual safety briefings, STIHL educates its workforce about waste management practices and demonstrates how each team member can personally contribute to these efforts. Our plant in Qingdao, China, set waste reduction targets in the reporting year and is promoting the reuse of pallets by both our plant and our suppliers. The ZAMA Group carried out a waste separation awareness campaign in the Philippines in the reporting year.

In 2024, the volume of waste was below the level of previous years. This is mainly due to the completion of construction work at STIHL Brazil. In recent years, a large number of construction projects at STIHL Brazil generated higher volumes of waste. Now that these activities have been completed, the amount of waste has decreased.

In the reporting year, we successfully implemented and/or moved ahead with a variety of projects aimed at making our packaging more environmentally friendly. By reducing the film thickness of our spare parts packaging by 20 percent, we will now save 16 tons* of plastic every year. A further 48 tons will be saved by eliminating the viewing window in our chain packaging. Switching to mono-materials additionally has a positive effect on the recyclability of our packaging.

All packaging for mower heads has now been converted to solid and corrugated cardboard, which will save 111 tons of plastic and 447 tons of carbon emissions per year in the long term. We now use standard-size paper sleeves instead of different-sized plastic bags to package our belts – a saving of almost a ton of plastic per year. We have also launched a project to make our finished tool packaging more environmentally friendly. The cardboard packaging with a white outer cover and black and orange print is to be gradually replaced by brown cardboard with black print. The project will be implemented by 2026 both at the founding company and at our production companies in the United States, Brazil, and China. STIHL is also testing whether it is possible to use 50 percent recycled material for film bags on our machines.

Our distribution center in Dieburg will permanently reduce its cardboard consumption by changing its packaging and shipping processes. In the future, we will use the container logic for 16 articles, which has the potential to save up to 11,500 boxes over the course of a year. Thanks to a newly acquired machine, we can also pack large and bulky items much more compactly, minimizing the use of oversized shipping boxes.

Converting our packaging allows us to make a contribution toward substantially reducing waste generation, a target under the goal “Sustainable consumption and production” (SDG 12).

*metric tons (1 metric ton = 1,000 kilograms)

in metric tons – values rounded

| 2024 | 20232 | |

|---|---|---|

| Total waste volume | 37,100 | 70,700 |

| Of which hazardous waste | 5,300 | 5,700 |

| 1 Production companies only; data collection to be expanded in the future. | ||

| 2 Updated figures following publication of the Sustainability Report 2023. | ||

in metric tons – values rounded

We take climate protection seriously and do our best to contribute wherever technically possible and economically viable. Since 2020, we have been striving to achieve long-term greenhouse gas neutrality in our operations across the value chain through calculated offsets. Our principle is that reducing emissions takes priority over offsetting. Our climate change mitigation activities make a contribution to the goal “Climate action” (SDG 13).

In order to support our climate targets, STIHL signed up to the Science Based Targets initiative (SBTi) and officially submitted our commitment letter in May 2024. As the next step, we defined specific targets for Scope 1, 2, and 3 emissions at the end of 2024, which will be adopted internally in 2025 and submitted to the SBTi for validation.

Scope 1 emissions at STIHL result primarily from the combustion of natural gas and heating oil to generate process heat for production and heating for buildings. We also record emissions from fuels used in development and adjustment processes in assembly and in our vehicle fleet along with all coolant losses under Scope 1. Scope 2 comprises indirect emissions from our electricity and district heating purchases.

Since the end of 2023, all STIHL production and sales locations worldwide have achieved greenhouse gas neutrality for their Scope 1 and Scope 2 emissions, calculated through the use of offset certificates and carbon sequestration by means of agroforestry (see “Climate protection projects”). At COSMOS STIHL Manufacturing, part of the STIHL Group since 2023, we collected the data needed to calculate emissions in 2024 and will decommission the associated certificates from climate protection projects in 2025. Such measures are still pending for our most recent acquisition, Mogatec. In the long term, we aim to reduce energy consumption and the use of fossil fuels throughout the Group. This will reduce the share of emissions from fossil sources, which we are currently still offsetting with financing contributions to climate protection projects outside our own value chain.

Emissions occurring in the upstream and downstream value chain (Scope 3) are not something the STIHL Group can influence alone. Nevertheless, we want to do our part in line with global and German climate protection targets.

In 2022, we looked into which Scope 3 emissions categories are relevant to us. In the upstream value chain, those areas include business travel, goods and services, waste, logistics, employee commuting, fuel production, and fuel transport. In the downstream value chain, we intend to consider the use and recycling of our products, as well as distribution logistics and packaging. In the reporting year, we pressed ahead with recording our product carbon footprints (PCFs), which involves determining the ecological footprint of a product over its entire life cycle in CO2 equivalents. An interdisciplinary team is now working on greenhouse gas accounting and, in 2024, also investigated the impact of materials on the greenhouse gas footprint of our products.

On average, the use phase accounts for 60 to 90 percent of our products’ emissions. Battery-operated products tend to lie on the lower end of the scale, depending on the local electricity mix. We have defined detailed Scope 3 reduction targets in connection with our commitment to the SBTi.

Our Group mobility management supports our Scope 3 targets. The mobility concept has three main components that are intended to reduce emissions in STIHL employees’ professional and private travel. It includes our Share & Go corporate car-sharing program for commuting between the plants of our founding company: Employees can use one of 13 vehicles (eight of which are fully electric). We are also pursuing further electrification of our vehicle fleet. In 2024, 14 new electric cars were added to the fleet at our founding company. With a total of 22 electric cars, around 17 percent of our vehicle fleet was electrified by the end of 2024. In addition, we will install a total of 130 charging points at the STIHL founding company plants by mid-2025, primarily for fleet, car-sharing and company cars, and 50 charging points will be available at the employee parking lot in Waiblingen. A new employee parking lot with 20 charging points was opened in Weinsheim at the end of 2024. Our distribution center in Dieburg has purchased a battery-powered flatbed vehicle for the Facility Management department’s plant traffic.

STIHL aims to make a net positive climate contribution with regard to Scope 1 and 2 emissions. To this end, we are active in three core areas:

Since 2022, all STIHL production companies worldwide have only purchased electricity from renewable sources. This is not possible at the ZAMA production sites in the Philippines, China, and Hong Kong because no green electricity is available on the regional markets. We are currently looking into the transition to electricity from renewable sources for COSMOS STIHL Manufacturing in the United States, and this is also planned for Mogatec in Saxony, Germany.

In the reporting year, we also pressed ahead with our plans to supply our own green electricity. A photovoltaic system (PV system) with an area of 4,800 square meters has gone into operation at STIHL Brazil. It generates up to 1.4 GWh of electricity annually and reduces carbon emissions by 210 tons per year. The Weinsheim site has installed a PV system with a maximum output of 600 kWp (kilowatt peak) on the roof areas; the new employee parking lot will be covered with a further PV system with a nominal output of 1,200 kWp. It will not only supply 20 charging points for electric cars – we will also use the surplus electricity generated to power the plant. We assume that the system will be able to cover the plant’s base load on nonproduction days and when there is sufficient sunshine. The two systems are expected to save a combined 1.73 GWh of purchased electricity per year. Our distribution center in Dieburg is planning to commission a PV system in 2025, which could produce up to 446,000 kWh of electricity per year, of which STIHL could use more than 80 percent to cover its own requirements. Our subsidiary ZAMA is also planning to install solar panels with a capacity of 250 kWp at its site in the Philippines during 2025. In the long term, 2,215 kWp of power capacity is to be installed at the site.

STIHL has set itself the goal of consuming 40 percent less fossil fuels by 2030 than it did in 2019. In our case, this primarily relates to natural gas and fuels. In 2019, consumption stood at around 150 gigawatt-hours (GWh). All Group companies have submitted corresponding action plans, which incorporate process optimization and technological innovations. We monitor progress in reducing consumption on a quarterly basis.

Electricity instead of gas – chain plant reduces carbon emissions

In the reporting year, our chain plant in Switzerland took a significant step toward reducing its emissions by converting the gas-fired heating system of a kiln line to electric heating elements. This reduces carbon emissions by 489 tons per year. The commissioning of a new, exclusively electrically heated hardening line is also planned for 2025. These two measures will reduce carbon emissions at the chain plant by 38 percent.

We also aim to reduce our energy consumption – our benchmark for energy efficiency – and improve the energy intensity in the process. In 2024, our energy intensity per 1 million euros in revenue stood at 147.2 MWh (previous year: 149.8 MWh, 2019: 197.8 MWh).

Our plant in Qingdao, China, introduced various initiatives to improve energy efficiency in the reporting year. Each machine now saves 21 kilowatt hours (kWh) of electricity per day thanks to the infrared insulation of the melting drums in injection molding machines. Increasing the cooling water temperature from 15 to 20 degrees Celsius will save 6,000 kWh per year, while the drying temperature of the resin dryer, which is now adapted to the variable moisture content of the resin, will save 19,000 kWh per year. In the year under review, STIHL Inc. in the United States procured an energy monitoring system that measures the consumption of electricity, water, gas, and compressed air for all plant-wide processes in real time. Our monitoring system immediately notifies us of consumption spikes, leaks, and inefficiencies, facilitating pinpointed equipment replacement. Installation is scheduled for 2025. In the reporting year, ZAMA optimized the cooling systems and compressors in the Philippines and ZAMA China put an electricity storage system into operation.

We adhere to the principle that reducing beats offsetting. To date, we have offset unavoidable Scope 1 and 2 emissions by purchasing and canceling certificates from climate protection projects.

In our view, it is crucial that the corresponding certification standards are internationally recognized, high-quality, and independent. For this reason, STIHL exclusively supports projects that have earned Gold Standard certification. These projects are also intended to support key targets from our sustainability strategy in addition to climate change mitigation. The related targets include “Good health and well-being” (SDG 3), “Gender equality” (SDG 5), “Decent work and economic growth” (SDG 8), and “Sustainable consumption and production” (SDG 12).

In 2024, we canceled certificates from two climate protection projects in the amount of the Scope 1 and 2 emissions generated in 2023. The projects are certified according to the Gold Standard and promote the supply of drinking water and the purchase of low-emission cooking stoves in Rwanda and Uganda. We will retire the certificates corresponding to the emissions generated in 2024 in spring 2025. In the reporting year, our agroforestry project in cooperation with Fairventures Worldwide also made its first contribution to climate protection by removing carbon dioxide from the atmosphere. Through the reforestation of deforested areas in Uganda and Borneo with over 1,000,000 seedlings, almost 10,000 tons of carbon was sequestered in the period between 2020 and 2024. In the future, we expect to contribute around 20,000 tons of carbon sequestration per year. As part of the project, local smallholders plant a mixture of crops and trees to contribute to their livelihoods and carbon sequestration. You can find out more about the project and the measurement of carbon sequestration here.

The energy management system at all German STIHL production plants has been certified in line with ISO 50001. We also strive to achieve continuous energy and cost savings by rolling out efficiency measures.

In the 2024 reporting year, our total energy consumption amounted to roughly 419 gigawatt-hours (GWh). This was slightly below the previous year’s figure (424 GWh). At 68 percent, the largest share of energy consumption is attributable to electricity, in particular for production, with natural gas accounting for 27 percent. Electricity consumption amounted to around 285 GWh in the reporting year (previous year: 285 GWh), while the consumption of natural gas amounted to 115 GWh (previous year: 118 GWh).

in GWh – values rounded

| 2024 | 2023 | 20192 | ||

|---|---|---|---|---|

| Natural gas | 114.8 | 117.8 | 133 | |

| Heating oil | 2.5 | 2.6 | 3.4 | |

| Fuel3 | 9.9 | 13.5 | 13.4 | |

| Renewable energy (geothermal heating and cooling) | 2.6 | 2.4 | 0.4 | |

| Total direct energy consumption | 129.7 | 136.3 | 150.2 | |

| Electricity | 285.4 | 285 | 279 | |

| Of which from renewable sources | 250.8 | 254 | 67 | |

| District heating | 3.5 | 2.5 | 1.1 | |

| Total indirect energy consumption | 288.9 | 287.5 | 280.1 | |

| Total energy consumption | 418.6 | 423.8 | 430.3 | |

| 1 Including STIHL Ventures GmbH and STIHL International GmbH, which are based at the founding company’s headquarters. | ||||

| 2 Base year. | ||||

| 3 Gasoline, diesel, and LPG for stationary and mobile applications. | ||||

in mwh per 1 million euros in revenue – values rounded

Measured in CO2 equivalents, the emissions generated by STIHL sites in Germany and our international production companies amounted to 46,491 tons in the reporting year (Scope 1 and 2 according to the GHG Protocol, previous year: 46,788 tons). We have offset these emissions with positive contributions from the climate protection projects that we support.

In line with energy consumption, CO2 emissions also fell in 2024. In 2024, around 88 percent (previous year: 90 percent) of our electricity requirements were covered by renewable sources (see “Clean energy”).

Our emissions are presented in accordance with the market-based approach. The calculation takes into account hazardous greenhouse gases under the GHG Protocol, the majority of which are carbon emissions. Although STIHL only generates negligible volumes of other greenhouse gases, the corresponding emissions are included for the sake of completeness.

in metric tons of CO2e – values rounded

| 2024 | 2023 | 20192 | ||

|---|---|---|---|---|

| Natural gas emissions | 21,410 | 23,695 | 27,210 | |

| Heating oil emissions | 637 | 699 | 900 | |

| Fuel emissions | 2,642 | 3,198 | 3,720 | |

| Coolant emissions | 1,550 | 1,623 | 1,860 | |

| Total direct emissions (Scope 1) | 26,239 | 29,215 | 33,690 | |

| Electricity emissions | 20,114 | 17,474 | 58,690 | |

| District heating emissions | 139 | 99 | 60 | |

| Total indirect emissions (Scope 2) | 20,252 | 17,573 | 58,750 | |

| Total emissions (Scope 1 and 2) | 46,491 | 46,788 | 92,840 | |

| Of which offset | 46,491 | 46,788 | 0 | |

| 1 Including STIHL Ventures GmbH and STIHL International GmbH, which are based at the founding company’s headquarters, | ||||

| 2 Base year. | ||||

Scope 1 and 2 in metric tons of CO2 per 1 million euros

in revenue, without offsetting – values rounded

The forest is the lifeline of our planet. It provides a home for countless animal and plant species, and is no less important for humans: Trees store carbon, we maintain the forest, and it serves us as a recreational area. STIHL has grown with the forestry industry and this places a distinct obligation on us to champion sustainable forest stewardship and development.

Sustainable forestry practices safeguard the future of our business while compelling us to act as responsible stewards. That is why STIHL condemns invasive and reckless forestry activity involving illegal tree felling, clearances by fire, or illegal clearances using heavy equipment – and not only in especially sensitive and biodiverse tropical rainforests. Such practices are harmful to the preservation of forests and, consequently, to the basis of our existence. Around the world, STIHL is committed to the sustainable use of forest resources and thus contributes to achieving the UN Sustainable Development Goal “Life on land” (SDG 15).

We support various reforestation and sustainable management initiatives around the world, primarily to alleviate damage to tropical rainforests. The connecting element? The projects combine ecological and social sustainability. Only by engaging local communities can we ensure the long-term protection of forests against destruction. To achieve this, parts of the already degraded areas must be managed in such a way that they can provide a livelihood for local communities. Only then can residents be won over to preserve existing forests and get involved in reforestation.

In Brazil, we have been supporting the Instituto Floresta Tropical (IFT) and, since 2023, the organization Meu Pé de Árvore (“My Tree”). During the reporting year, we continued our reforestation efforts by planting seedlings in degraded Amazon basin areas with our project Juntos plantamos mais! (“Together we plant more!”). We rely on an agroforestry approach for these projects. In addition to endemic tree species, economic plants are also planted on the land for the local population.

In Germany, STIHL supports Bergwaldprojekt e.V., a nonprofit organization that works to protect, maintain, and preserve forests.

Our Group member ZAMA continued its reforestation project in 2024 for the fourth year, focusing on ten hectares of mountain land planted with the Narra tree, a national symbol of the Philippine archipelago. By August 2024, 2,000 trees had already been planted, and the aim is to plant 5,000 by 2027. By the end of 2025, five hectares of wetlands are to be planted with 12,500 mangrove seedlings in another sponsored project; by March 2024, 10,000 seedlings had already been planted. Together with other companies in the Santo Tomas industrial park, ZAMA employees also planted 2,500 trees to mark Philippine Forest Day.

STIHL is committed to supporting research and aid projects that develop concepts and approaches for sustainable forestry in selected zones of the tropical rainforest. We plan to continue to actively engage with nongovernmental organizations (NGOs). STIHL is a long-standing cooperation partner of the NGO Fairventures Worldwide. This NGO reforests degraded areas in Uganda and on Borneo in Indonesia together with local communities on the basis of an agroforestry approach. Farmers receive seedlings of native trees and various food crops that they can plant as intercrops. This generates income without destroying rainforests or monocultures. In the long term, the trees also store carbon, making an important contribution to climate protection. Roughly 500,000 seedlings were distributed in the reporting year alone, helping reforest more than 680 hectares. Fairventures also succeeded in acquiring more than 600 new participating local farmers. Since its inception, the partnership has planted more than 918,000 trees on 2,409 hectares of land. You can find out more about the project and the measurement of carbon sequestration here.

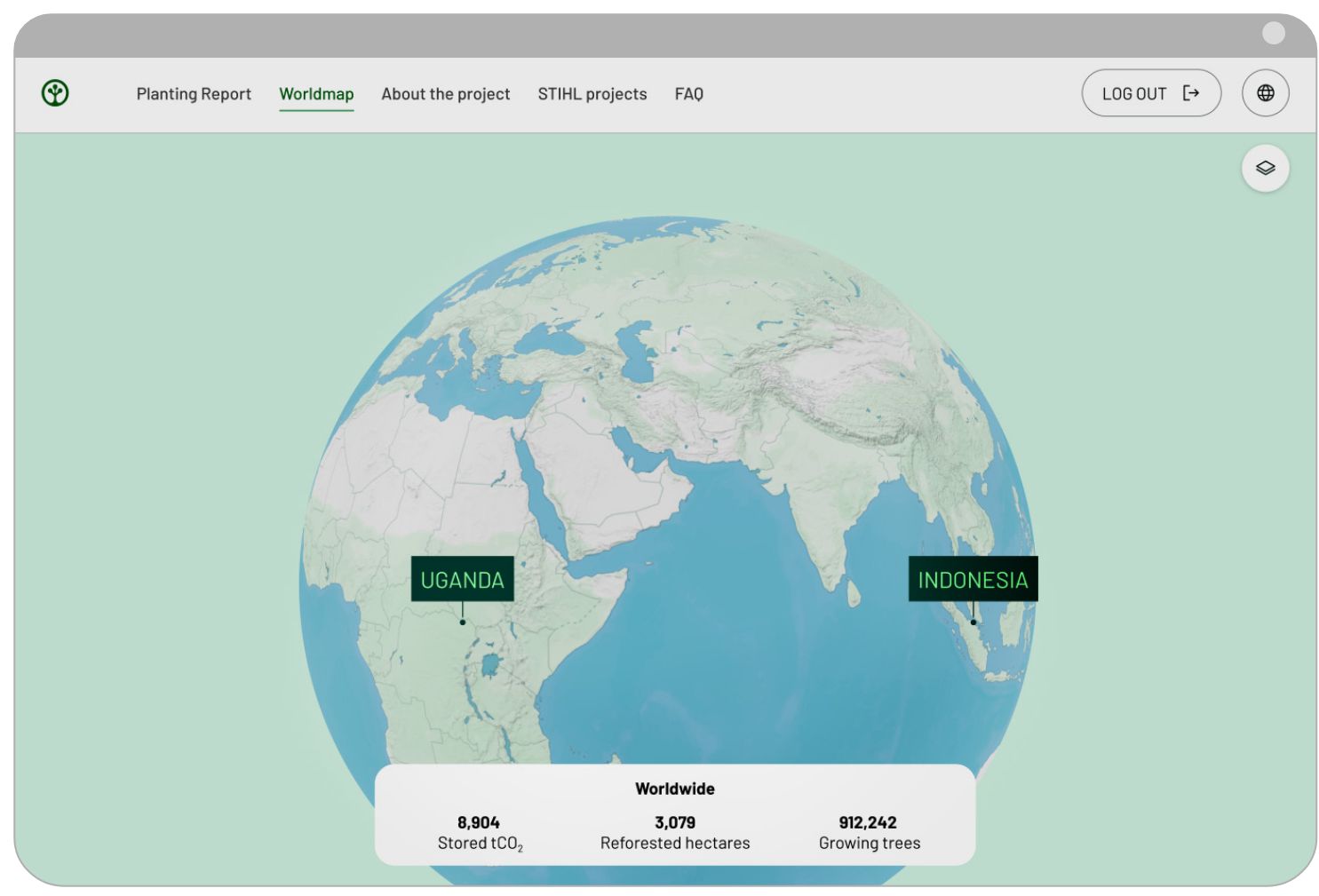

Sustainable reforestation of deforested areas, secure and verifiable sequestration of carbon: To achieve this, STIHL supports reforestation projects. In TREEO, STIHL has a partner that combines technology with a solid scientific foundation and social commitment.

Explore the reforestation areas in Uganda and Borneo that STIHL is realizing together with Fairventures Worldwide.

For many years, STIHL has been engaged in reforestation projects in cooperation with the Stuttgart-based NGO Fairventures Worldwide: Together, they support smallholders in Uganda and Indonesia with planting trees on depleted land. In doing so, they also contribute to climate protection by sequestering carbon from the atmosphere.

The partners have taken their collaborative efforts to a new level with the aim of pursuing this goal even more consistently and presenting it as transparently as possible: TREEO, an app developed by the Fairventures subsidiary Fairventures Digital, calculates, discloses, and monitors the carbon sequestered by each individual tree. “The crux of many reforestation projects is that companies pay for the trees to be planted – but mortality rates are high, and after a few years, customers no longer know whether the forest they purchased still exists and is sequestering the predicted amount of carbon,” explains TREEO cofounder and CEO Stefan Ferber. “We use TREEO to provide traceability and transparency over the entire lifespan of the trees.”

»We measure the carbon stored in each tree annually using the TREEO app. We demonstrate that transparency is possible when it comes to sustainable reforestation projects for climate protection, biodiversity, and social impact.«

Stefan Ferber TREEO cofounder and CEO

The seedlings are cultivated in tree nurseries, while farmer field schools teach small-scale farmers the theoretical and practical basics. The selection of participants is strict and is based, among other things, on reliability and a long-term approach. “It’s not just about planting the seedlings,” adds Ferber, “it’s about tending to them.” Especially during the first year or two after planting, because many seedlings would die otherwise. This is why a community approach is being pursued in which “villages, parishes, or schools with established structures make the success of reforestation less dependent on individuals.” After a few years, the trees can be felled and sold as lumber. Tree prunings are converted into biochar, which is used to improve the soil. Alternatively, the trees are left standing to provide protective cover for decades.

The seedlings have been grown from native tree species. Instead of monocultures, the focus is on mixed cultures comprising two, four, or six different species.

To date, TREEO has focused on reforestation organizations in Uganda and Indonesia. On the TREEO data dashboard, customers can navigate to “their” plantations and zoom in on individual trees and their respective carbon sequestration capacity on an interactive world map. The dashboard shows the number of trees as well as the measured and predicted sequestration levels, and updates these based on the individual measurements. The calculation methods are based on both tree- and region-specific growth models. Based on the annual individual tree measurement, each carbon sink is recorded in the Carbon Standard International Register, assigned to the buyer, and decommissioned.

The TREEO app is ideally adapted to conditions in the partner countries: It also works offline and even on older Android phones.

At the heart of the climate technology start-up TREEO is an app of the same name: Once a year, the participating farmers hold the red TREEO card against their trees and take a photo of them. The app calculates the carbon sequestration capacity based on the reference size on the card, the trunk diameter, the tree species, and the age of the tree. Simultaneously, GPS data for each tree is recorded along with the photo. TREEO validates each dataset, compares it with satellite images, drone recordings, or on-site visits, and stores it in a database. The data is then visible on the customer dashboards – for maximum transparency and a high level of credibility.

The farmers are paid for these annual measurements and the resulting amount of sequestered carbon documented. In this way, TREEO combines climate protection and social development: “We believe in helping people to become business owners, not recipients of donations from a charity-run project,” says Stefan Ferber. “The principle is ‘My tree – my money.’”

Together with its pilot customer STIHL, TREEO has developed its dashboard into a storyboard: Although it was originally designed for a specialist target group of sustainability officers or teams and was complex in terms of the data involved, in the future it should appeal to the wider workforce and any other interested parties. The layout and content are now more clearly arranged and appealing: In addition to key data on the trees planted, the app contains engaging background reports and useful information on the reforestation projects.

You can find the storyboard here:

dashboard.treeo.one/stihlhectares of reforested area

digitally measured trees

tons of sequestered carbon

(In each case as at January 2, 2025)