Thinking further, going further

For nearly 100 years, STIHL has been a technology leader. We see that role as both an obligation and a source of inspiration. Our goal is to make it easier for people to work in and with nature. To do so, we develop products and technologies that combine innovation, quality, and durability.

Our founder, Andreas Stihl, attached great importance to both the constant advancement of the products made by STIHL and the expansion of the portfolio in order to constantly meet the customer’s needs. In 1959, he revolutionized forestry work by launching the STIHL Contra, the first gearless gasoline-powered chainsaw. Based on the technical foundation laid by the Contra, STIHL has worked tirelessly to further enhance its chainsaws. From the antivibration system (first installed in the Contra in 1965) and intelligent engine management for reducing fuel consumption all the way through to technologies engineered to reduce emissions, the first chainsaw with magnesium pistons for weight reduction, and battery technology, STIHL’s focus to this day has always been on performance, durability, comfort, safety, and environmental protection.

Our customers have high standards. In order to meet them, we have always maintained an impressive depth of development expertise and aim to fully understand and master all of our technologies and products. To ensure the desired premium STIHL quality, we expect the same of our suppliers as well. Our international and interdisciplinary development team makes sure that our products offer the best possible combination of performance, durability, and ergonomics. That way, our customers get products that meet or exceed regulations and technical standards regarding fuel consumption, emissions, and noise, for example. Through innovation, we are working to cement our market leadership.

Sustainable product innovations

Low-emission

MotoMix Eco

Our new fuel makes operating two-stroke engines more environmentally friendly. MotoMix Eco contains 10 percent ingredients from renewable sources, reducing CO₂ emissions by at least 8 percent compared to the classic MotoMix fuel while delivering the same level of performance. As a member of the eFuel Alliance, STIHL is helping advance the development and acceptance of synthetic liquid fuels from renewable energy sources across the industry.

HSA 100

More user-friendliness and less noise are the hallmarks of the new HSA 100 cordless hedge trimmer, which is 70 percent quieter than its predecessor and can be used for longer in noise-sensitive environments.

Innovative

MSA 300

The STIHL MSA 300 is the most powerful cordless chainsaw on the market today. Despite having low impact on people and on the environment, the flagship model in the series is designed for demanding jobs in forestry and other sectors. Compared to gasoline-powered saws, the MSA 300 is quieter and emission-free for its immediate surroundings.

Cordless product advisor

STIHL launched a pilot version of a digital cordless product advisor in 2022. Initially available in Germany, the system allows users to filter their online searches to find battery-operated tools and charging solutions that are an optimum fit for their needs and expectations. Our goal with the advisor is to encourage people to switch to cordless products and to show them tailored options for their equipment.

iMow

In 2023, we plan to launch the latest generation of our iMow robotic mowers. They combine high performance, optimized mowing times, perfect cutting patterns, and easy use by app or smart home technology with intelligent operation and charging.

Award-winning

bottTainer

The innovative power of our products receives regular recognition from independent institutions. Germany’s national horticulture and landscaping association Bundesverband Garten-, Landschafts- und Sportplatzbau, for example, awarded the bottTainer powered by STIHL its innovation medal in 2022. In partnership with the in-vehicle equipment manufacturer bott, we have developed the industry’s first flatbed-loading system that can be used to safely transport batteries from our AP system and charge them directly on location. We have also added a new top-of-the-line option to our AP professional battery system: The AP 500 S is the most powerful battery in the series. With 337 watt-hours of energy, it helps double charging cycles and delivers a substantial increase in service life.

HLA 56

Our battery-operated HLA 56 extended-reach hedge trimmer is a winner. In August 2022, the German consumer testing organization Stiftung Warentest wrote: “The only good trimmer is the one from STIHL, which is even capable of handling thick branches.” With an impressive overall score of 1.9, it achieved the best reviews by far in its category. The testers – who looked at 15 cordless hedge trimmers, including five extended-reach models – also singled out the above-average battery runtime.

Quality

STIHL products have always been known for their particularly long service life, repairability, and high quality. It is not uncommon for them to be handed down from generation to generation, underscoring our commitment and conserving resources at the same time.

We consistently live up to our quality standards, as reflected in a wide range of testing techniques, many of which were developed in-house. Where possible, our focus is on use-oriented techniques, such as examining the steel composition of various alloys and performing vibration, noise, and other durability and quality tests. We also test our saw chains and examine the contents and chemical composition of the fuels and lubricants we develop. More importantly, however, we have defined quality as a corporate target based on key performance indicators that we analyze regularly to make adjustments and improvements as necessary.

With regard to sustainability, we further honed our marketing and sales promotion focus on our quality standards and the corresponding features of our products in 2022. The message: With STIHL, customers get efficient and durable products that help conserve resources.

Part of keeping our quality promise to our customers includes making sure that properly trained authorized dealers are available to handle the maintenance and repair of our tools, should it become necessary. Tools such as saw chains can be sharpened, helping them achieve excellent performance over a long service life. With our patented Hexa cutting system, we recently started making it possible even for non-commercial users to sharpen saw chains the easy way. To keep our tools working for as long as possible, spare parts are available for at least ten years or longer after we stop making a particular series.

In keeping with our STIHL quality commitment, the right-to-repair legislation that the European Commission is planning for consumers is also on our agenda. The proposals address concerns raised by the right-to-repair movement, which is dedicated to achieving a universal right to have devices and appliances repaired, unencumbered access to repair services and tools, and the reduction of global resource consumption. In 2022, STIHL adopted Group-wide guidance containing a standardized definition of how we understand this issue. We are committed to making our products repairable. An analysis of repairability plays an important role in the development of any new product. To contribute to sustainability through durability, among other objectives, we also want to make it possible for our customers to access service and repair information, as well as spare parts.

At the same time, STIHL is meeting its responsibility to protect consumers from illegal modifications, manipulations, or improper alterations of parts that are essential to its products’ environmental and/or safety performance. Our guidelines therefore also provide guidance and recommendations on which repairs should continue to be performed by authorized dealers only.

Research and development

A product is only as good as the people who develop it. That is why STIHL is committed to continuously expanding and enhancing its research and development (R&D) activities. In 2022, we increased the number of employees in R&D by a significant margin at our founding company’s offices in Waiblingen, Germany, alone – from roughly 700 to more than 900. Around the world, just over 1,200 engineers and technicians from a variety of fields work to improve existing STIHL technologies and develop new ones. Most recently, our focus has been on amassing expertise in fields such as digitalization, robotics, sensors, and artificial intelligence.

Our global network of businesses ensures that R&D at STIHL is always closely tailored to the requirements and conditions of local markets and our production sites. To this end, engineers at the production companies around the world provide regular feedback in order to ensure the manufacturability of a product design and to ensure that the product is well suited for the markets in which it will be sold. The overall responsibility for all R&D activities lies with the Executive Board member for Research and Development at the German founding company, where corporate product development is based. What all projects have in common is that they must meet the strict guidelines of our STIHL product development process, which are defined in our Group-wide directives.

As of 2022, our development team has registered more than 2,600 patents. Many of those patents strengthen our sustainability commitment directly. Our automated patent analysis tool makes it possible to attribute patents to the United Nations Sustainable Development Goals (SDGs). Accordingly, most of the attributable patents contribute to reducing emissions and therefore have an impact on SDG 13 (climate action), SDG 3 (good health and well-being), and SDG 9 (industry, innovation, and infrastructure). Overall, our R&D activities allow us to enhance scientific research and upgrade technological capabilities – a contribution to achieving one of the targets of the United Nations Sustainable Development Goal SDG 9.

Drivers of innovation

In recent times, ever-stricter exhaust and emissions standards for internal combustion engines have been fueling a surge in innovation, especially in the battery segment served by STIHL. The U.S. state of California, for example, has set hydrocarbon (HC) and nitrogen oxide (NOx) limits of 0 grams per kilowatt-hour for certain products starting on January 1, 2024, which equates to a de facto ban on internal combustion engines. For this and other reasons, we are focusing our R&D activities both on the further optimization of our tools powered by internal combustion engines and on the expansion of our expertise in battery development. Our goal is to maintain our leading market position in the gasoline-powered segment and leverage further potential through technologies such as low-CO₂ fuels, while continuously enhancing our position in the field of battery-operated tools.

In its search for the best solutions, STIHL is also in close contact with external experts at universities and other institutions, such as Prof. Michael Bargende, Chair of Vehicle Drives at the University of Stuttgart. For more than 20 years, his research input has helped us achieve breakthroughs time and again. On top of that, we regularly carry out research in cooperation with colleges and universities. In the field of innovation alone, over 60 students wrote their undergraduate or graduate thesis at STIHL in 2022 on topics such as battery technology, battery recycling, or sustainable lubricants.

Expertise in digitalization and electronics

For many years now, STIHL has been dedicating its efforts to exploring the opportunities associated with increased digitalization. In 2022, we further enhanced our organizational focus on digitalization in the area of hardware and incorporated it into our development activities, allowing us to optimize our processes and create synergies. Through stronger links between individual fields, we aim to leverage even more of the potential of digitalization for our business and our customers. The use and analysis of data (“big data”), for example, has the potential to enhance the efficiency of how we manage production or further optimize the sale and use of STIHL equipment when it comes to factors such as fuel and electricity consumption. What is more, operating data lets us know where we can make changes to improve the way products are engineered. Through our expertise in the development of software and apps, on the other hand, we aim to continue enhancing the user-friendliness of our tools.

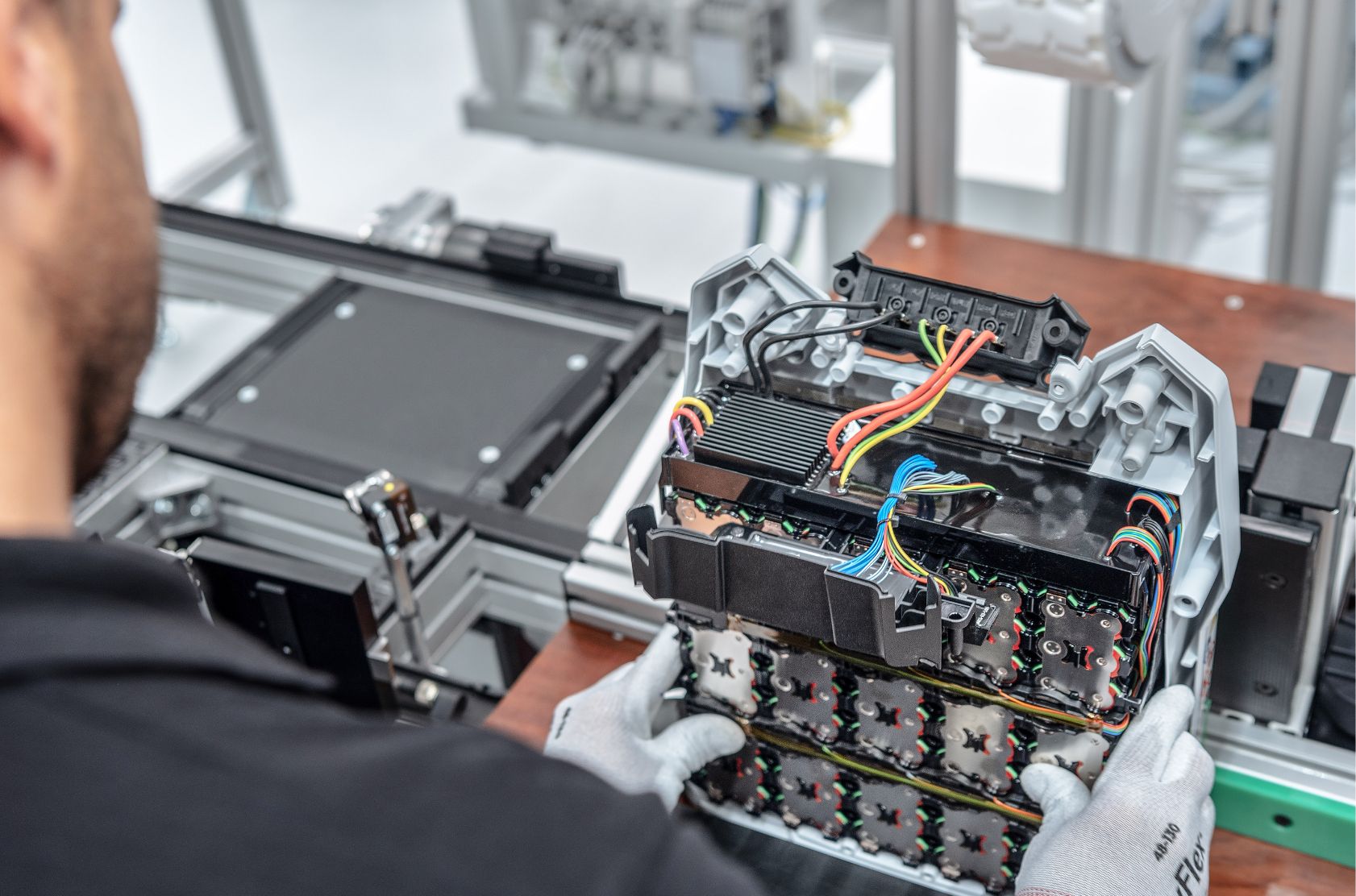

STIHL is investing in fields such as robotics, sensors, and artificial intelligence in order to offer its customers complete solutions and round out its data expertise through the hardware to match. In 2016, we opened a state-of-the-art center of excellence for battery and electrical technology in Waiblingen, Germany. In 2021, we further enhanced our battery strategy by teaming up with the Elrad International Group to found a joint venture for the production of electronic assemblies.

Circular economy

Circularity plays an important role in the STIHL sustainability strategy. The goal of a sustainable circular economy is to minimize the use of resources and the production of waste, in line with the principles reduce, reuse, repair, refurbish, and recycle.

At the STIHL Group, we pay attention to the efficient use of materials from the very start. The durability and repairability of our products also help conserve resources. The reuse and refurbishing of products likewise have the potential to make an important contribution to a functioning circular economy through new business models and innovations built around product-as-a-service solutions and other concepts that involve using a product for a fee rather than buying it outright.

In line with the goal of a sustainable circular economy, we follow the 5 Rs:

Devices or tools no longer fit for use can be recycled as a final step – an aspect that is at the center of our battery-powered products in particular. Authorized STIHL dealers may take back portable batteries depending on their obligation to do so, and recycle them in cooperation with different disposal companies in the respective countries.

In line with the goal of a circular economy, we aim to enhance our processes and products in order to conserve resources. When developing new products, we pay particular attention to using recyclable components. We aim to make our products reusable to the greatest extent possible, with a material recycling rate of over 85 percent in accordance with ISO 17341. To this end, we launched a two-year pilot project in late 2022 to investigate the potential of developing a clearing saw that is fully circular in both manufacturing and use. For capacity reasons, we were forced to postpone a potential analysis on increasing the percentage of secondary raw materials until 2023. The analysis was originally scheduled for 2022. However, we still held a kickoff workshop for our environmentally critical raw materials strategy, which we plan to develop by 2024. By 2025, we aim to also draw up an action plan for avoiding hazardous process chemicals.

Product safety

The safety of our customers while they work with our outdoor power equipment is essential. Compliance with technical standards, the latest technological developments, and legal requirements is the foundation on which our products are built. Because STIHL is a member of the working groups that define global ISO and IEC safety standards, systematically promoting the advancement of safety requirements is part of our corporate philosophy. STIHL’s internal findings on the strength of guards and handles, and on electronic circuits and sensors, for example, have been incorporated into international standards, allowing us to share our knowledge with the world.

As a technology leader, we look back with pride on the many innovations STIHL has pioneered that have made an important contribution to increasing the safety of customers. Since 1972, for example, the Quickstop® chain brake has been helping saw chains come to a full stop in a fraction of a second. To ensure that our safety philosophy is fully understood by users, authorized dealers provide product instruction and safety training that buyers in our online shop can also take advantage of. Our RESCUE SAW MR – Mixed Reality Emergency Services Saw Simulator virtual training platform, which has already received multiple awards, demonstrates how modern technology can contribute to greater safety. The platform was designed with a focus on enabling emergency response teams from fire departments and civil protection organizations to practice the safe handling and proper use of chainsaws and emergency services saws in a digitally augmented training environment.